Vulcan’s Welded Helical Solid Finned Tubes are manufactured with by helically wrapping fin strip on edge around the tube circumference and continuously welding the fin strip to the tube. The fin strip is held under tension and confined laterally as it is formed around the tube, thereby ensuring that the strip is in forceful contact with the tube surface. A continuous weld is applied at the point where the fin strip first begins to bend around the tube diameter using Vulcan’s unique gas metal arc welding (GMAW) process. This weld process creates the strongest fin to tube attachment in the industry, excellent heat transfer characteristics, low fin-side pressure drop and little to no change in grain microstructure and physical characteristics even when 3%-9% chromium tubes are used.

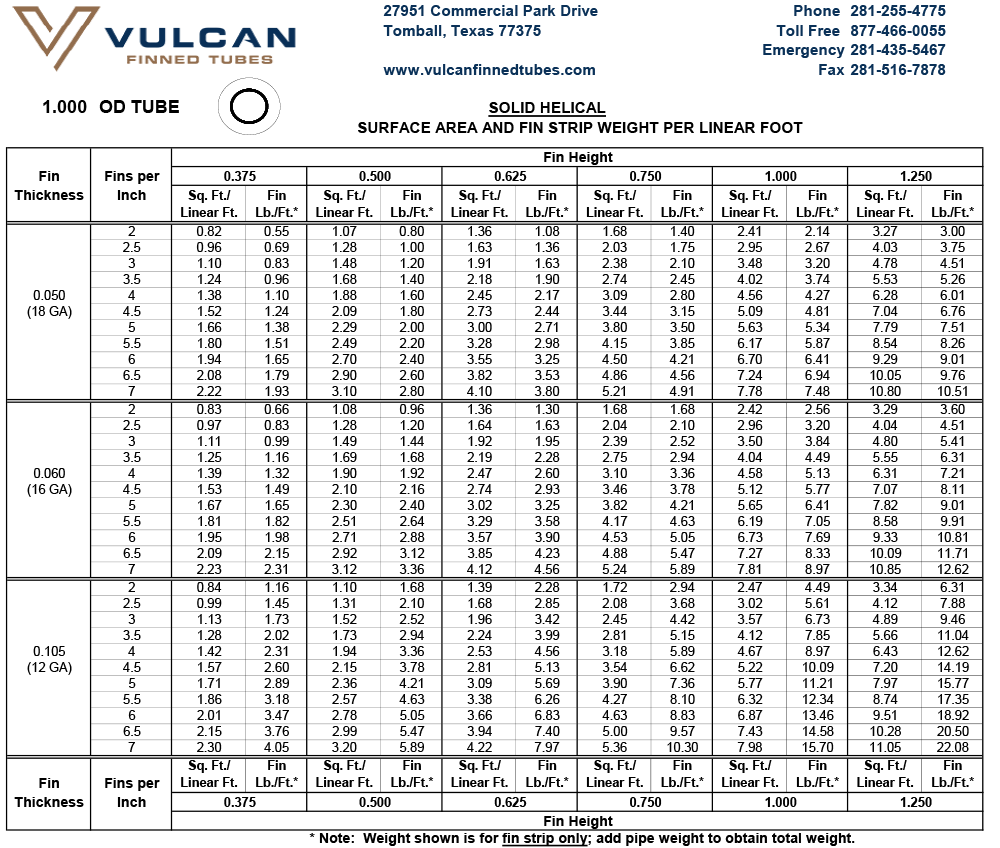

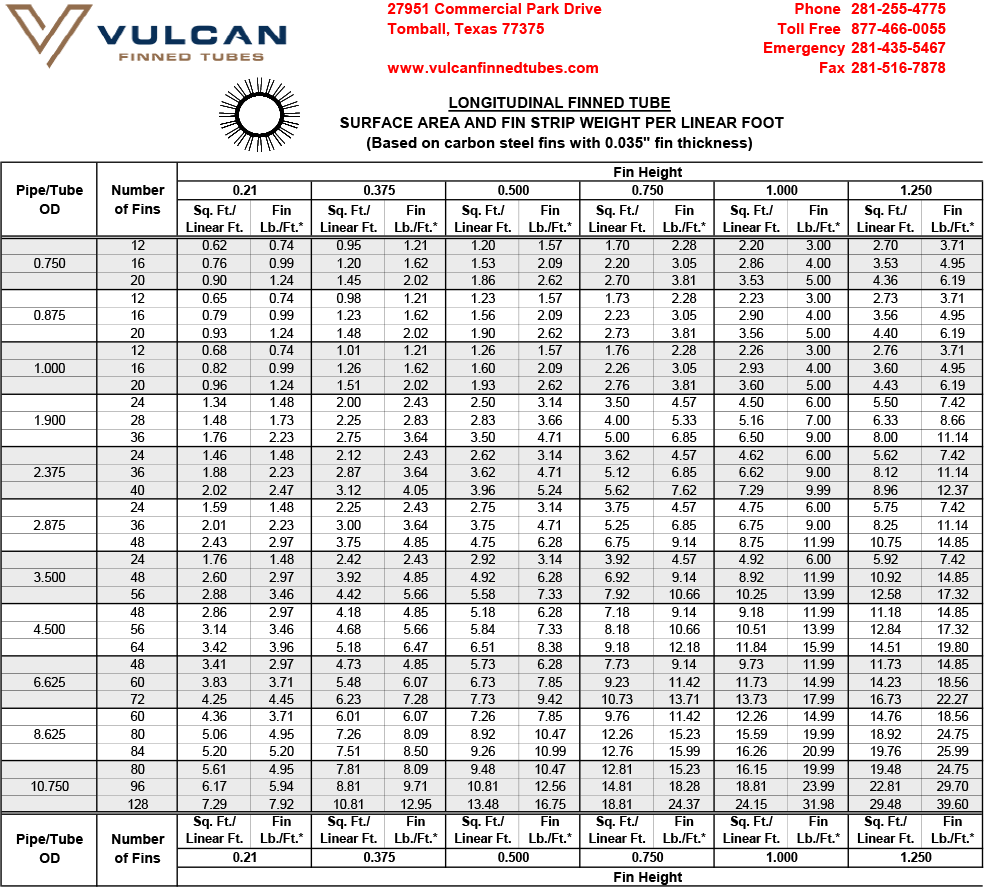

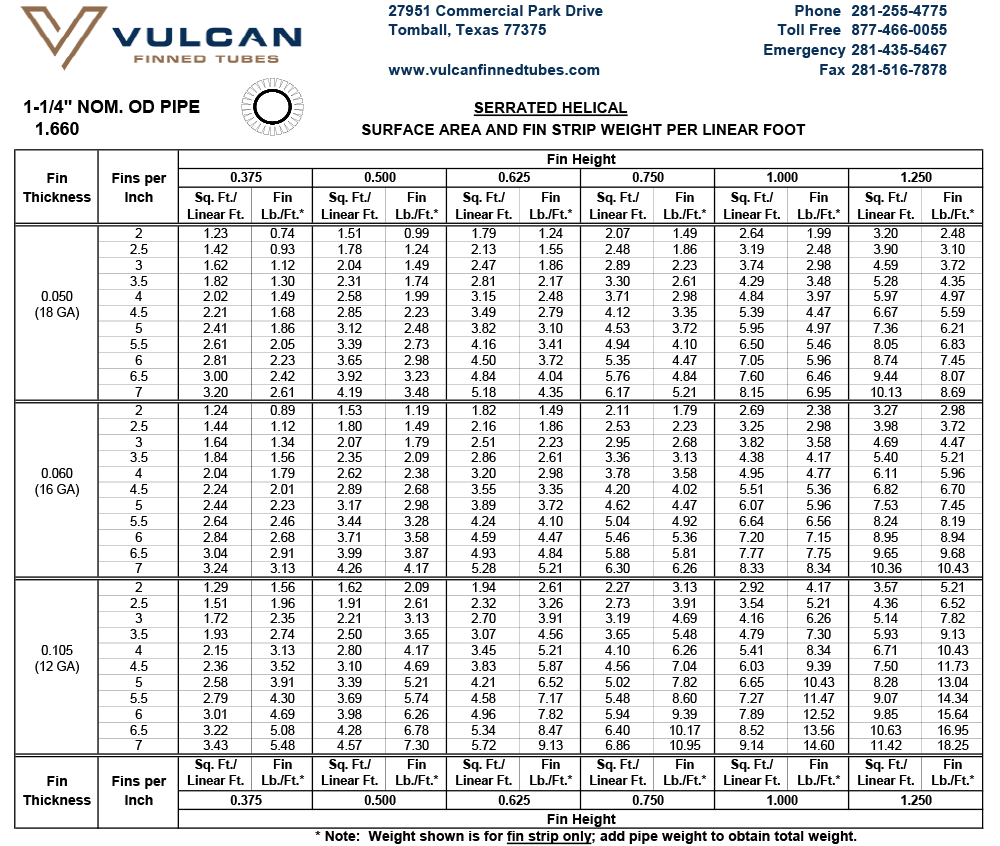

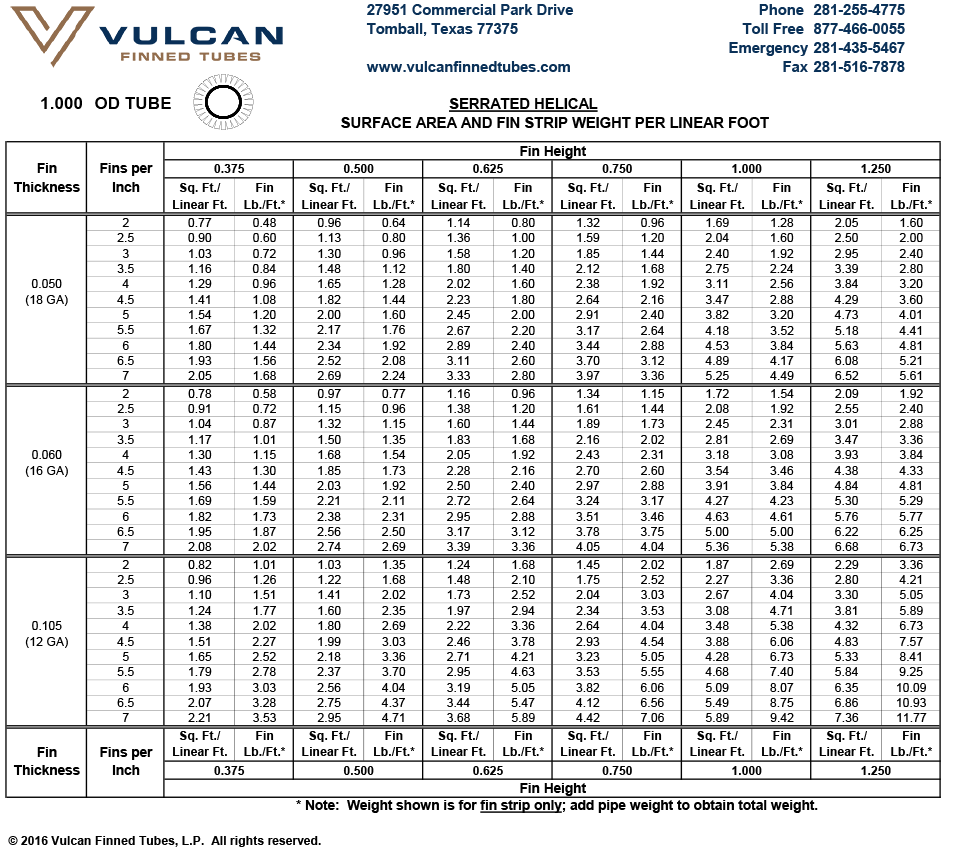

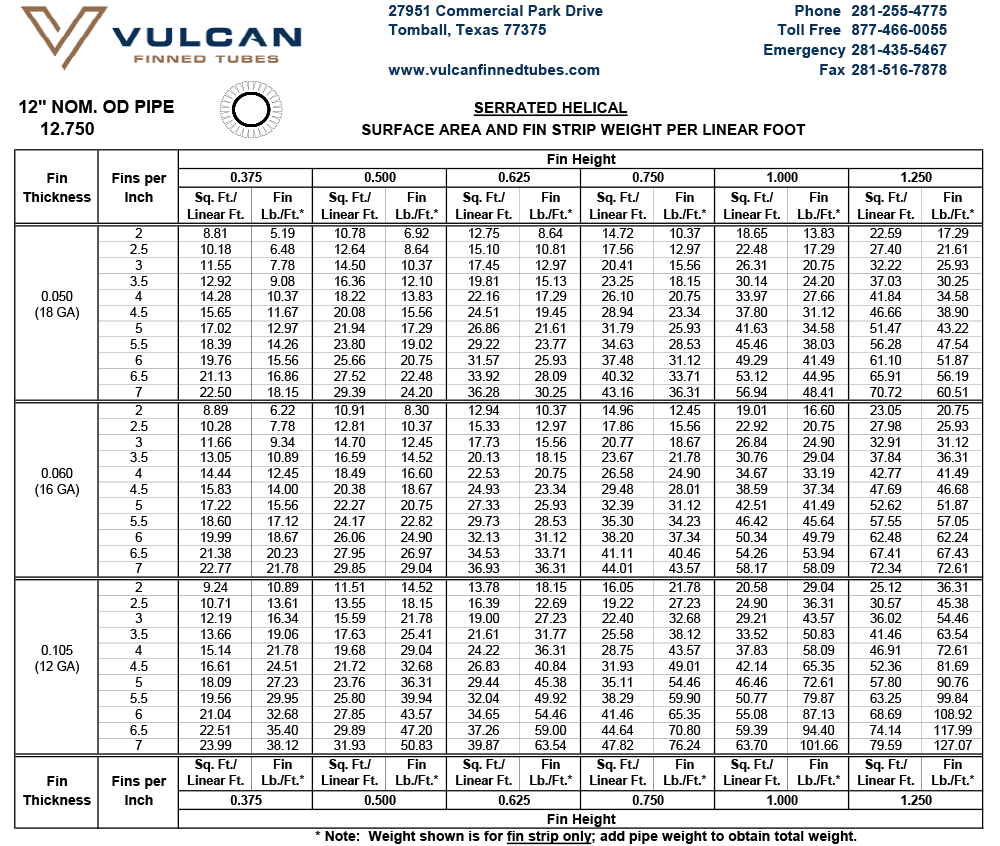

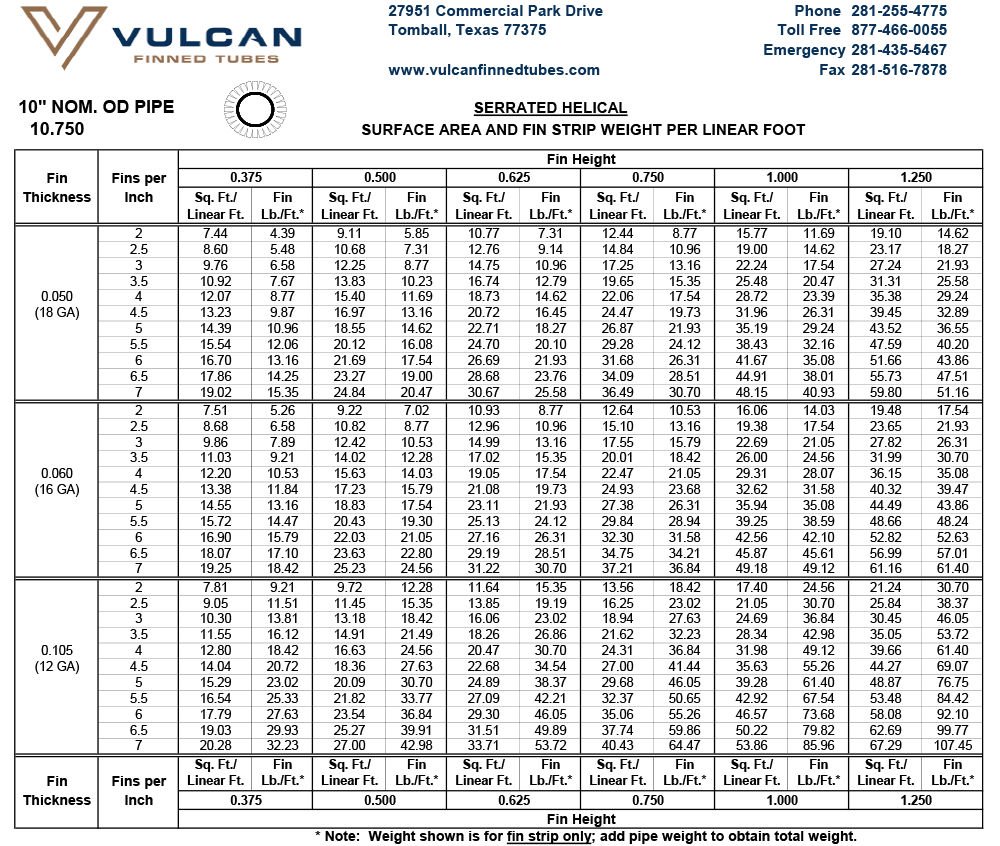

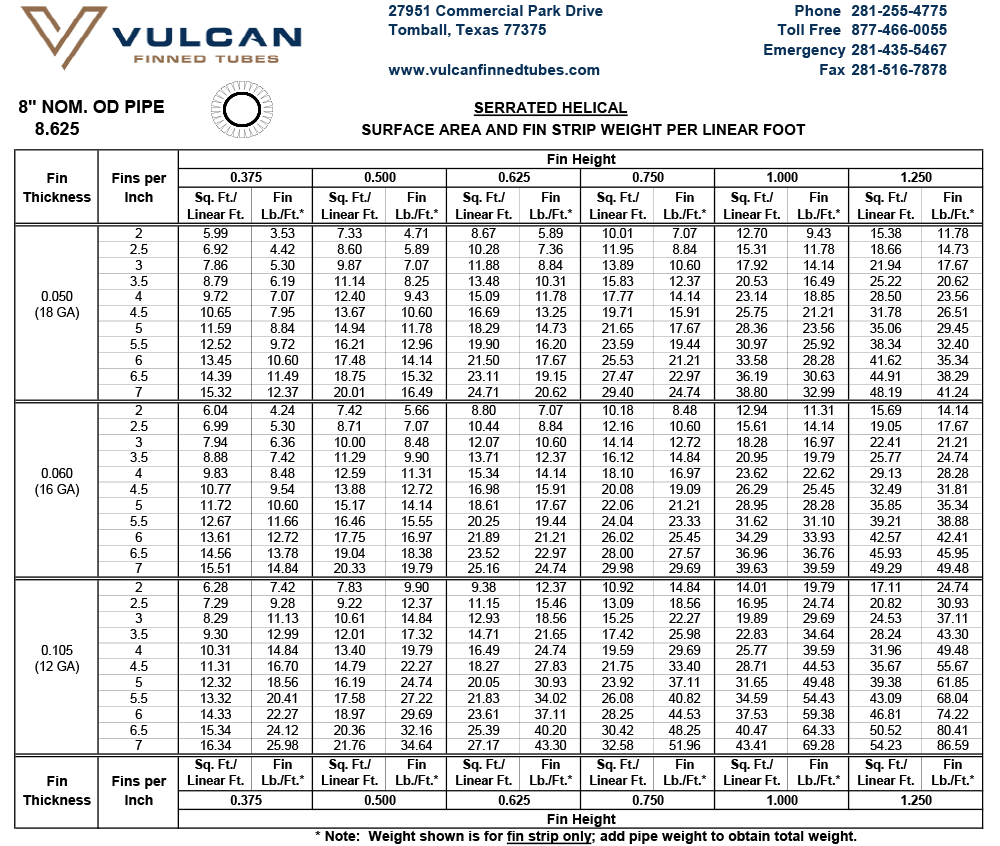

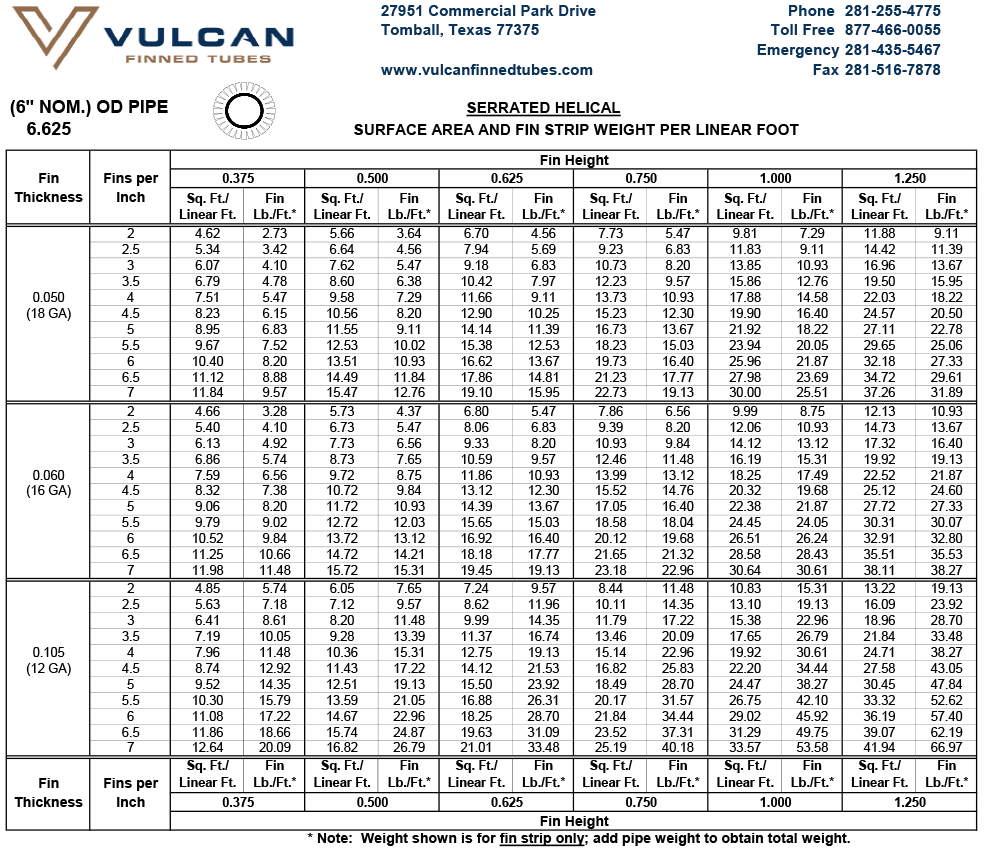

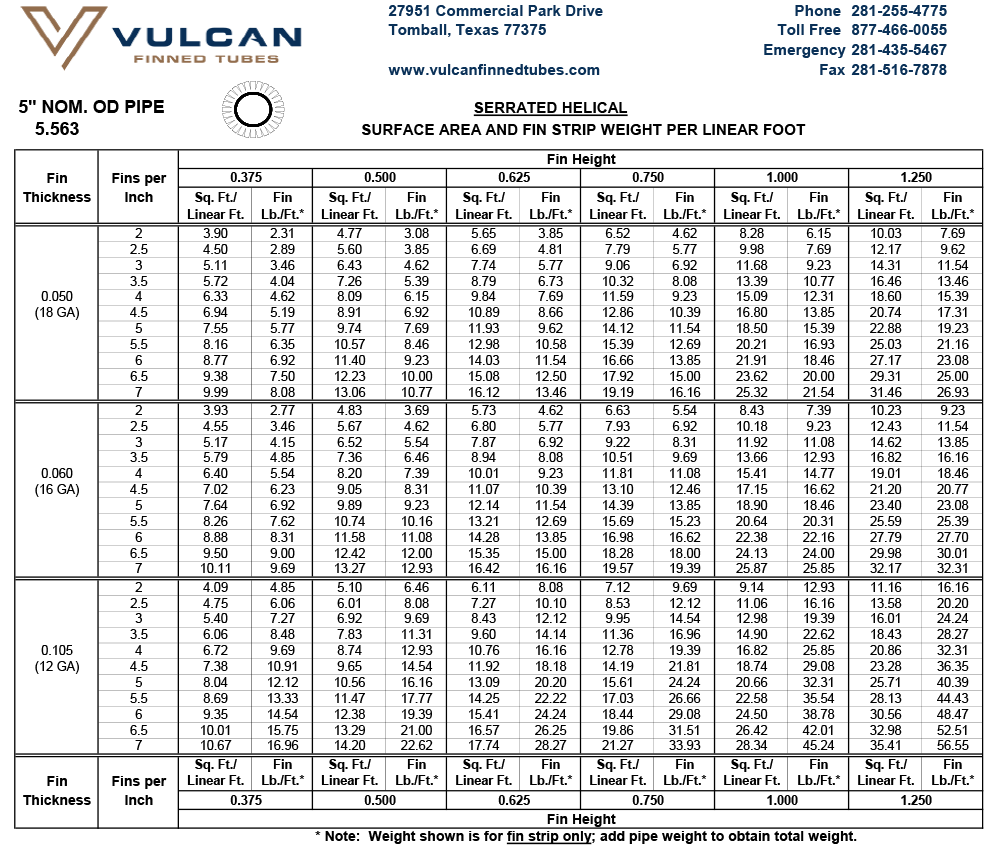

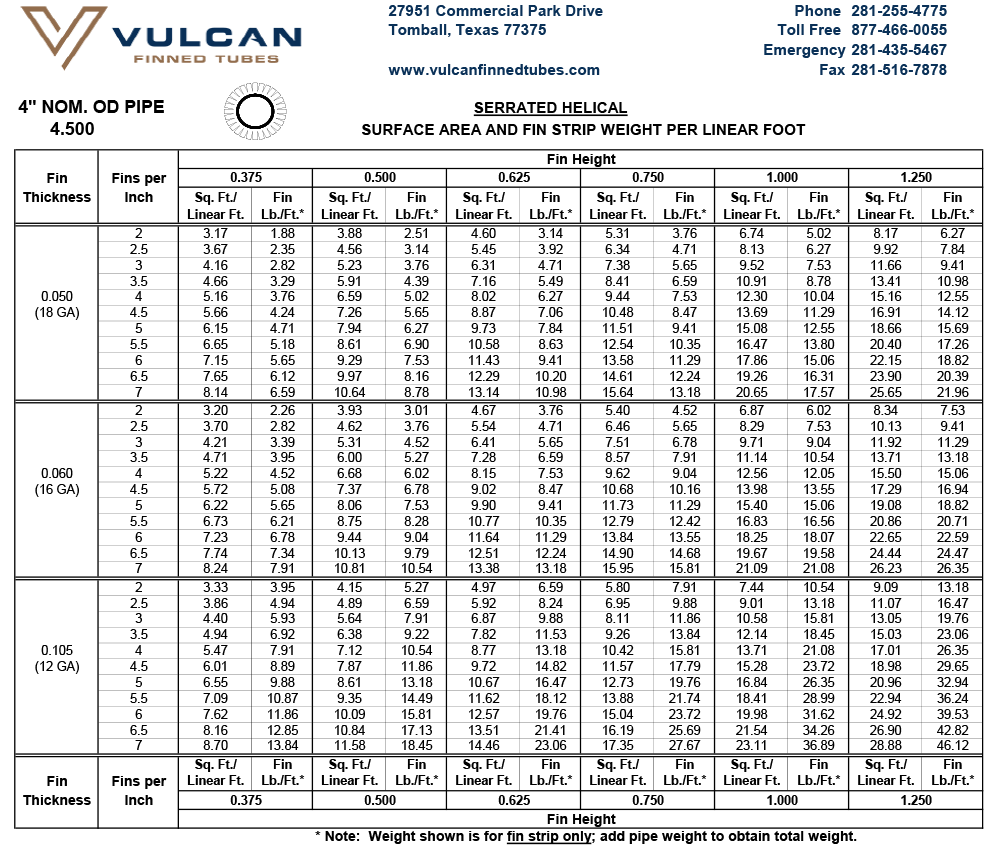

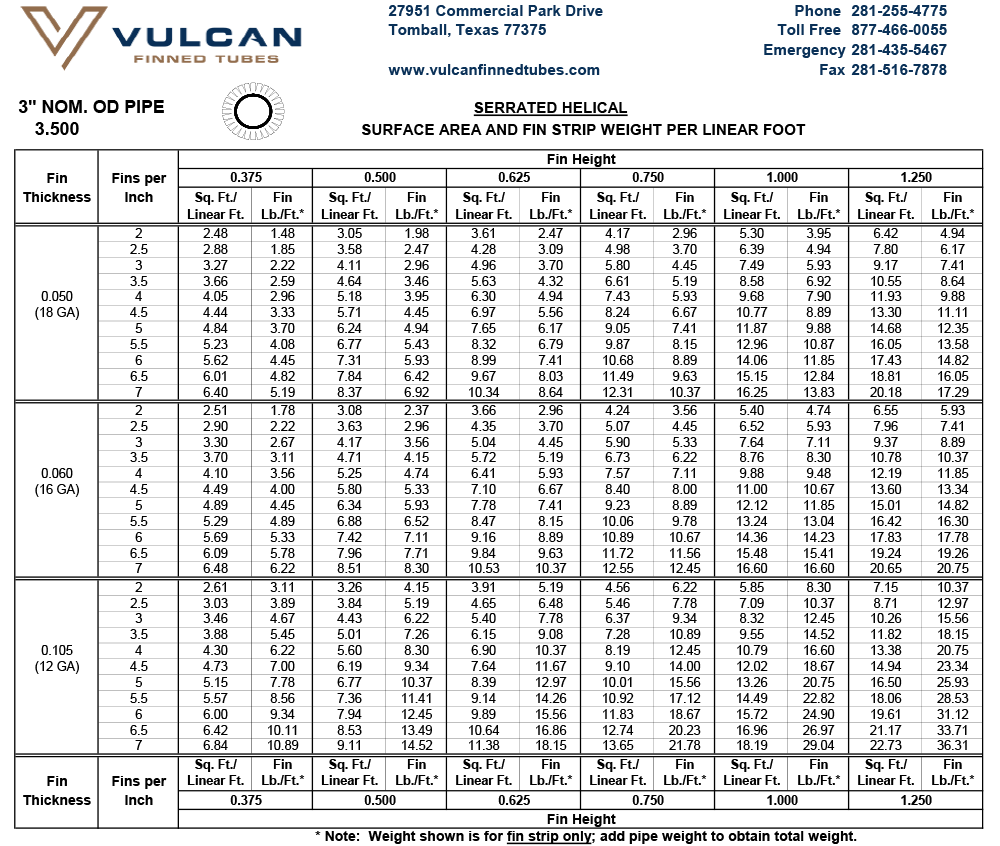

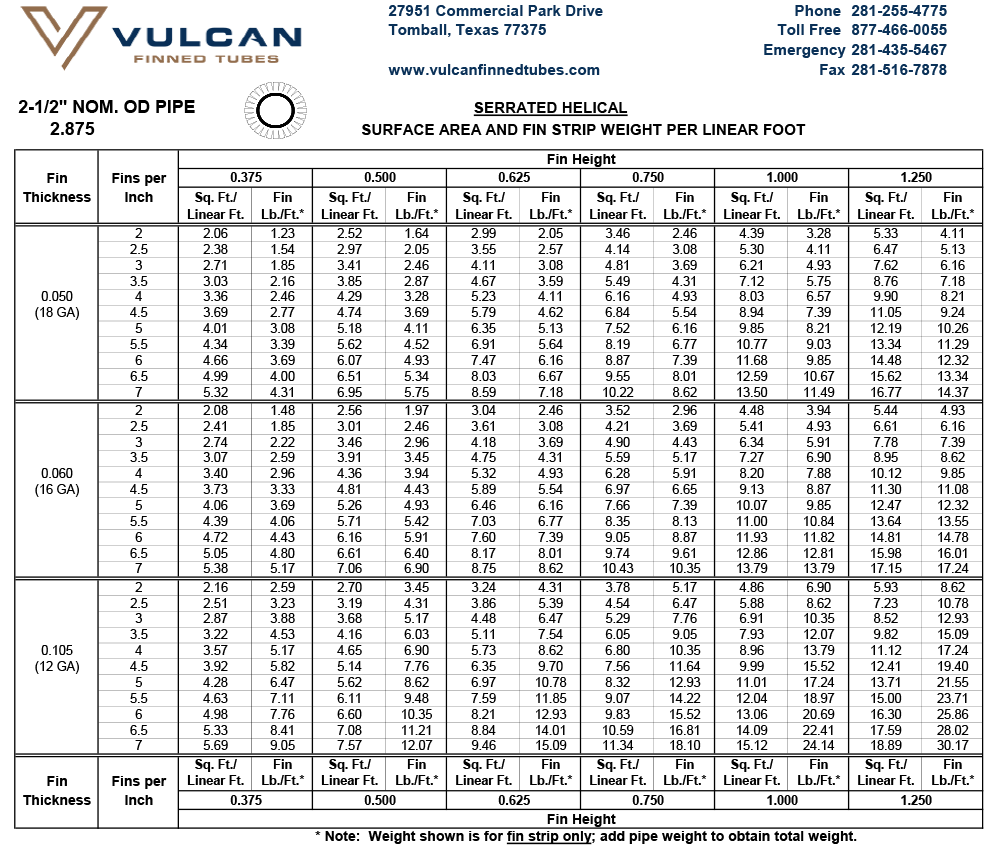

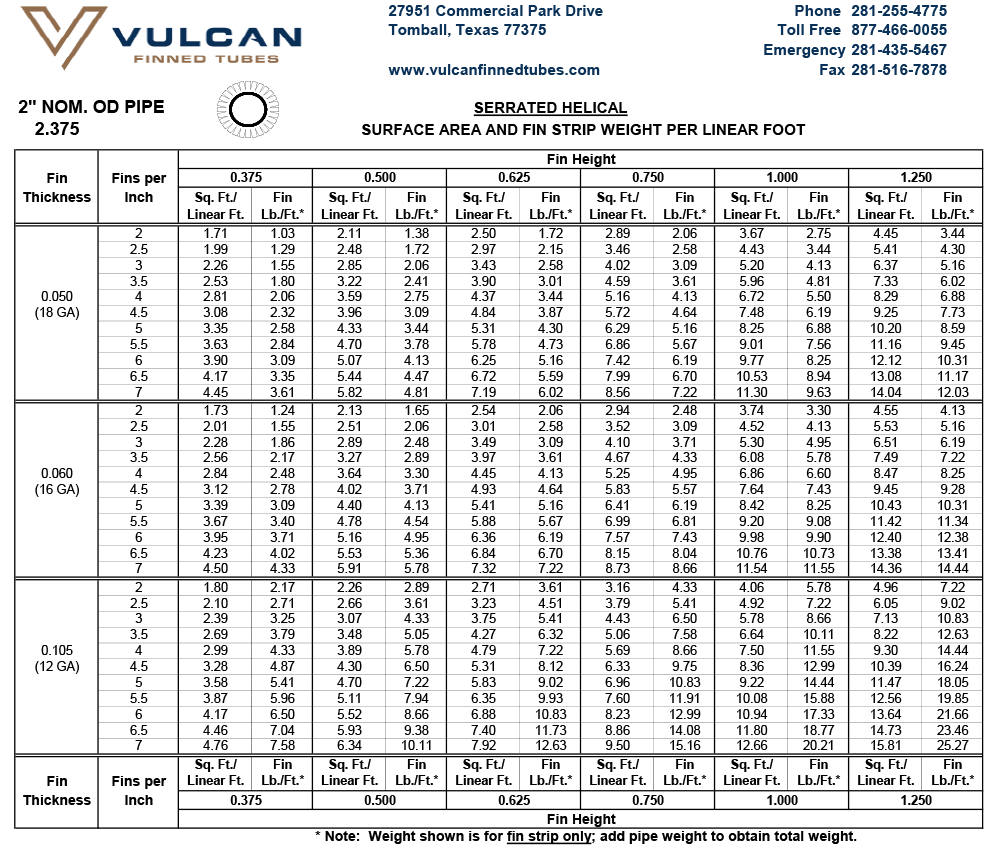

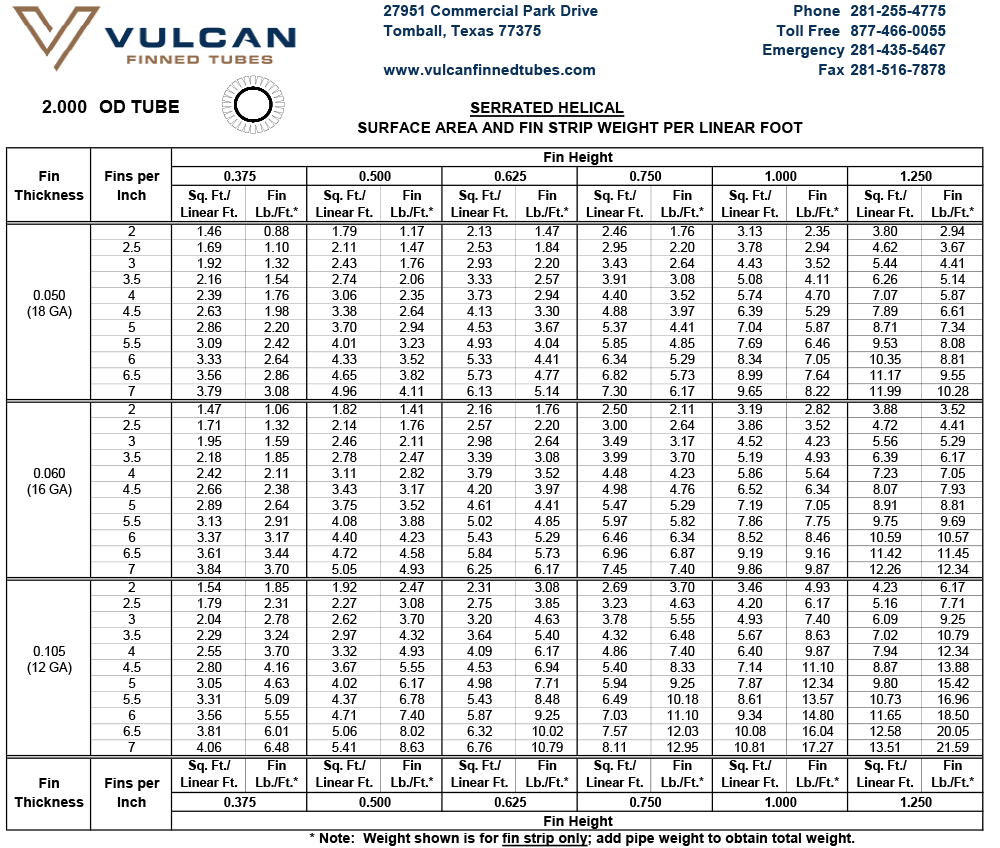

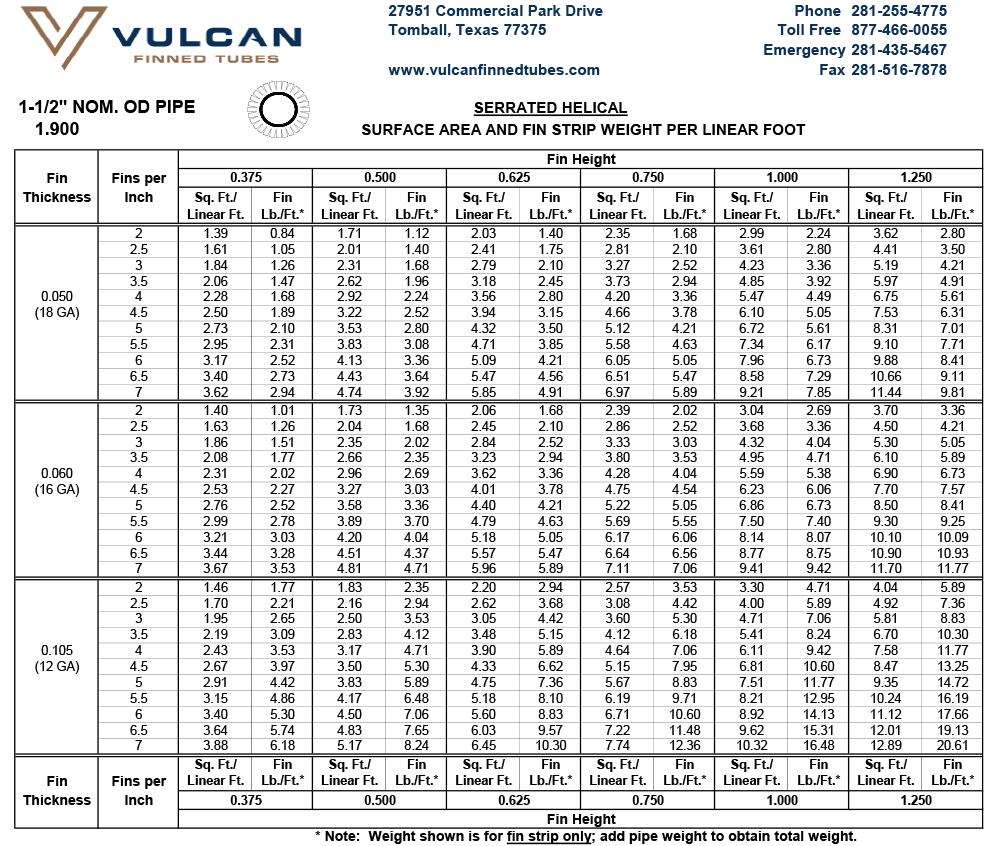

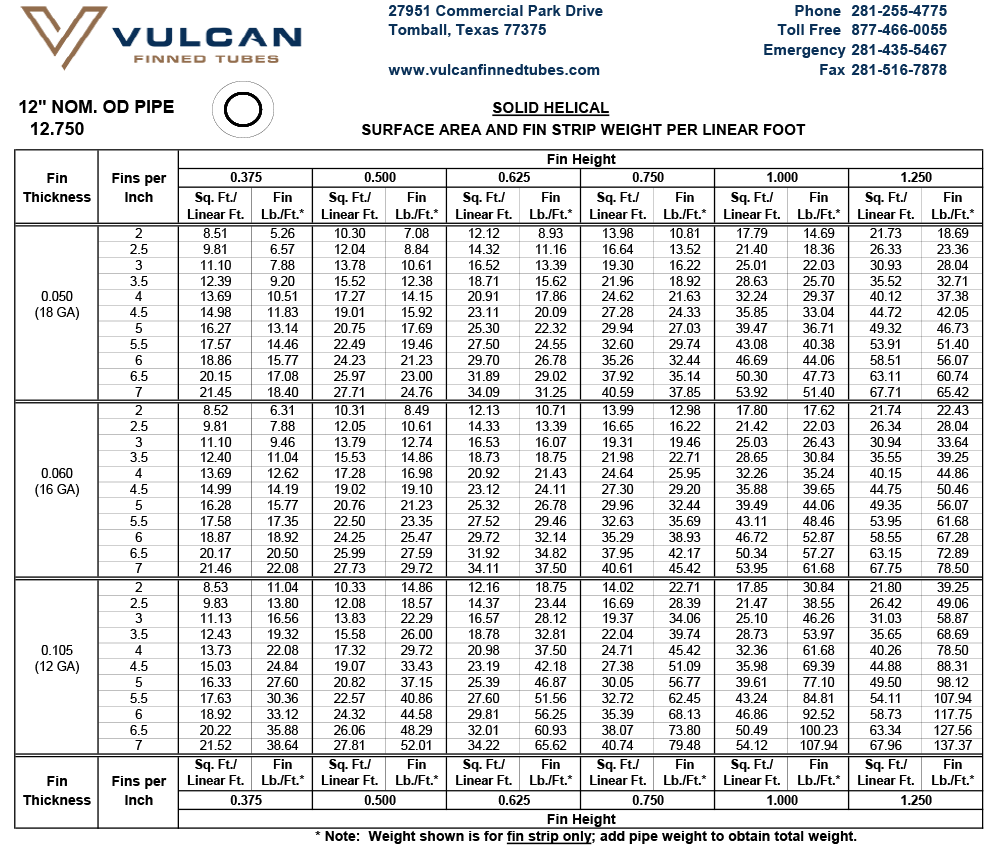

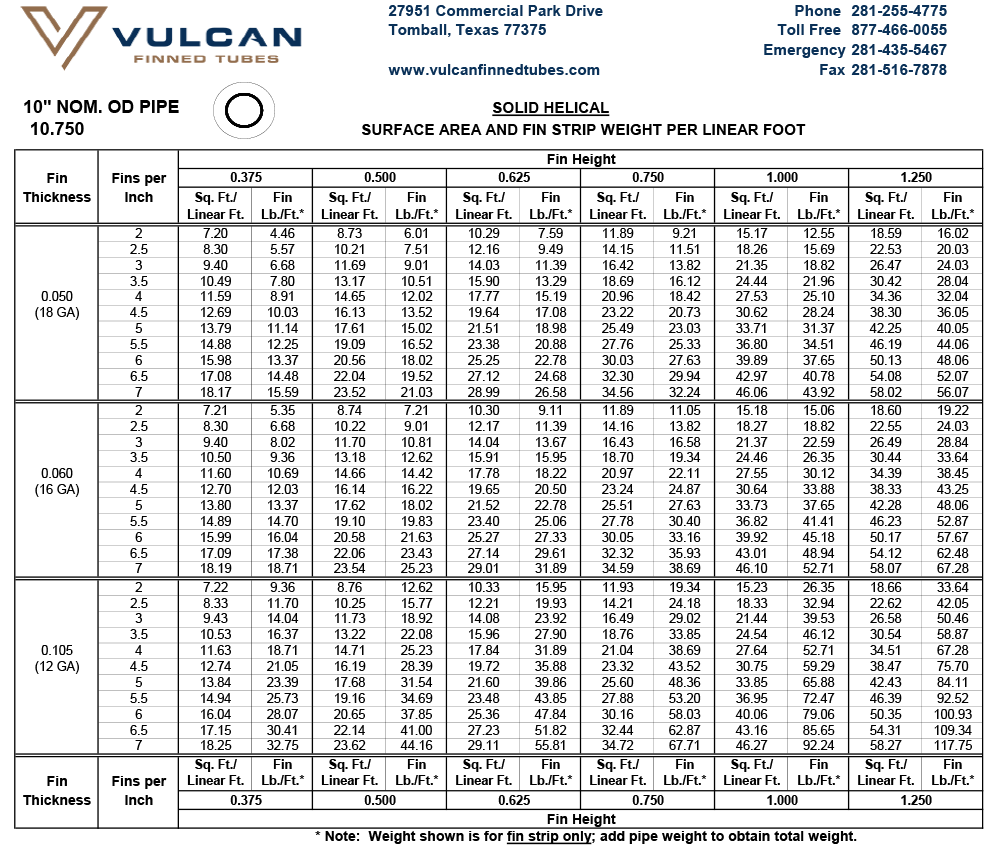

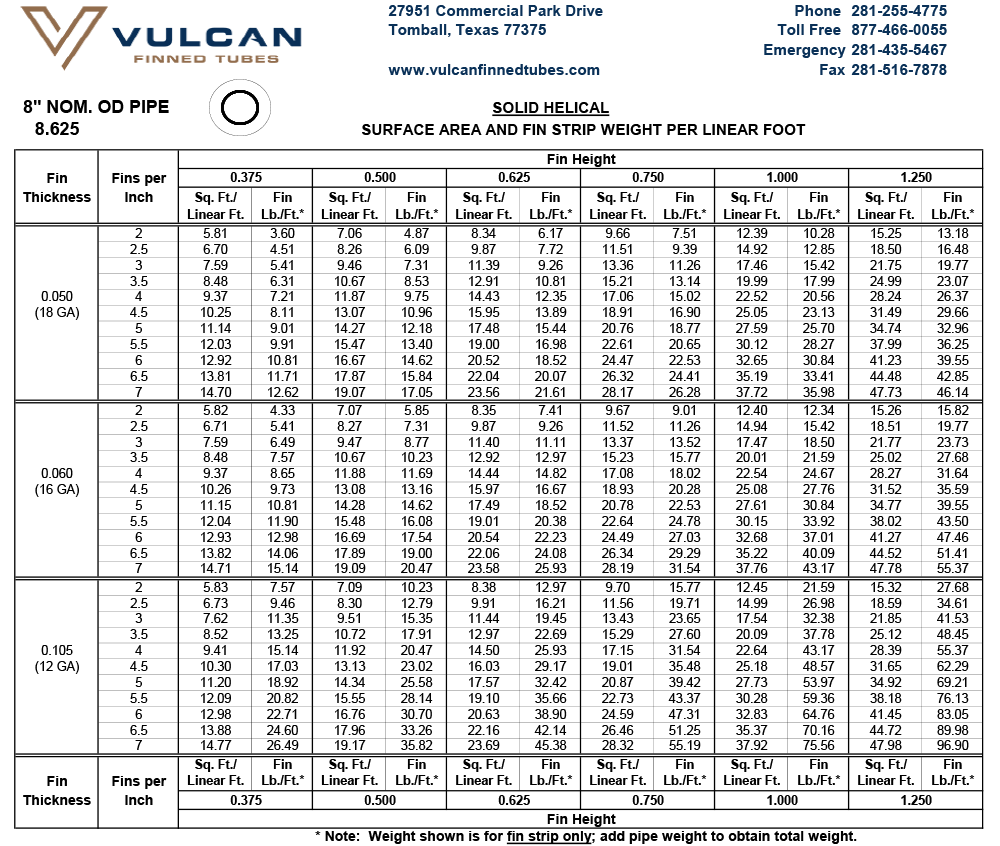

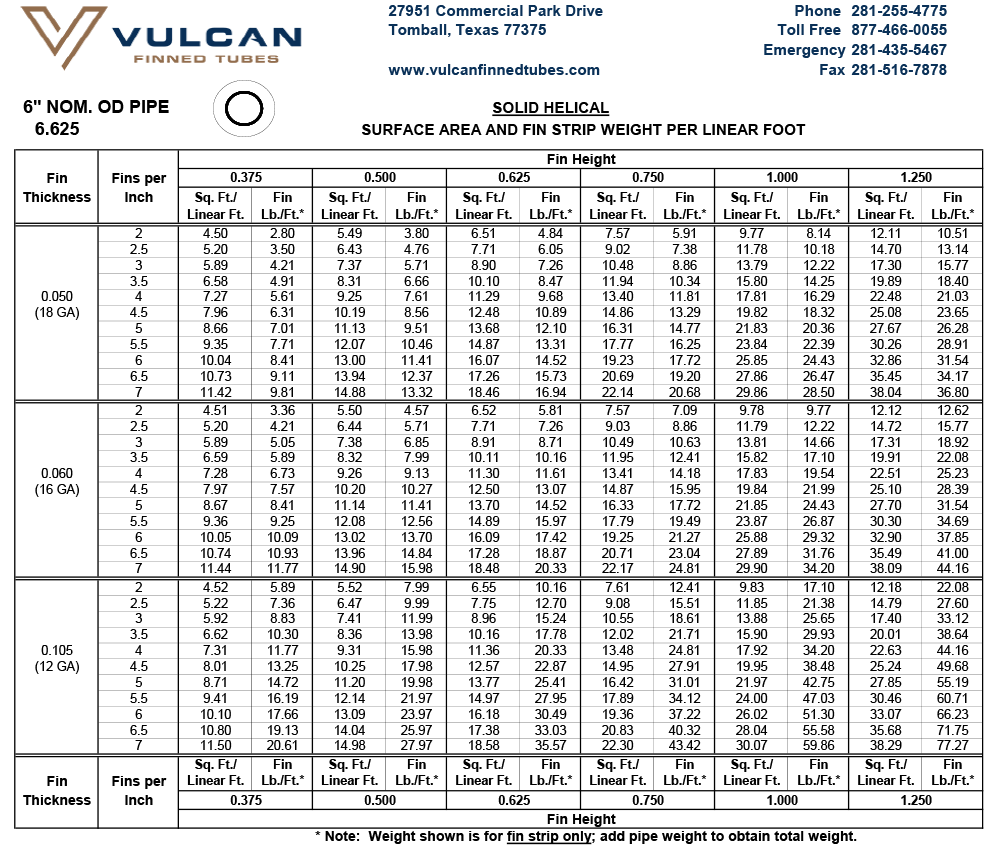

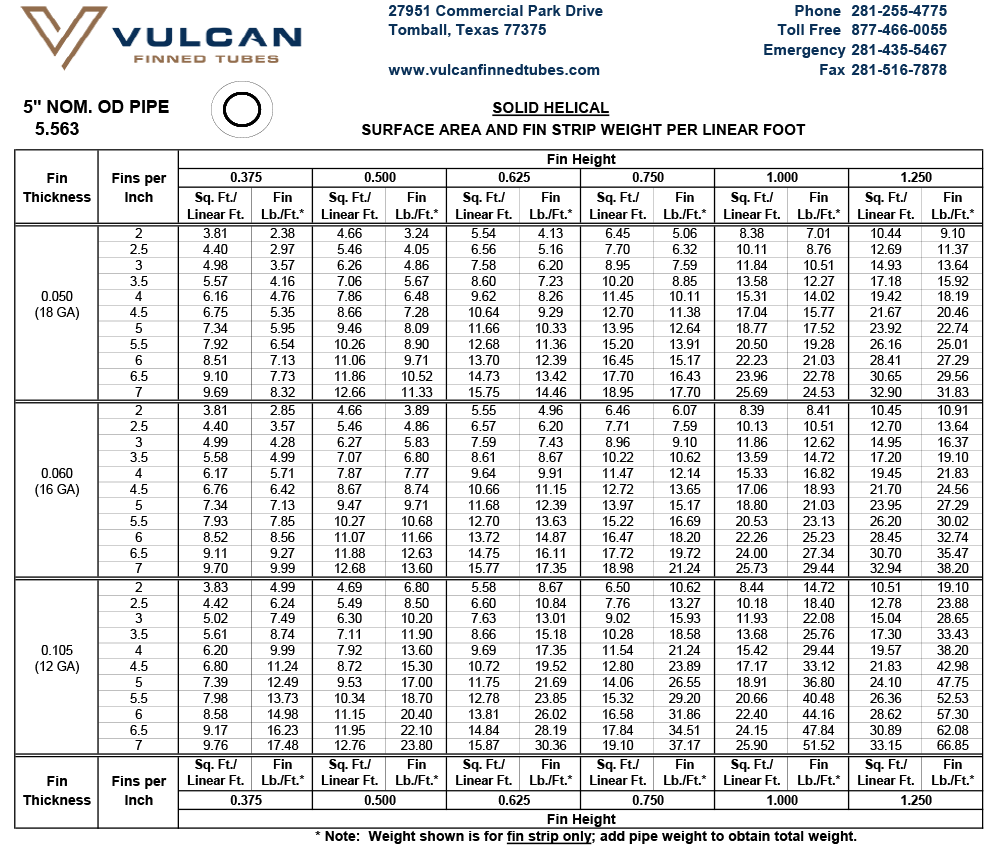

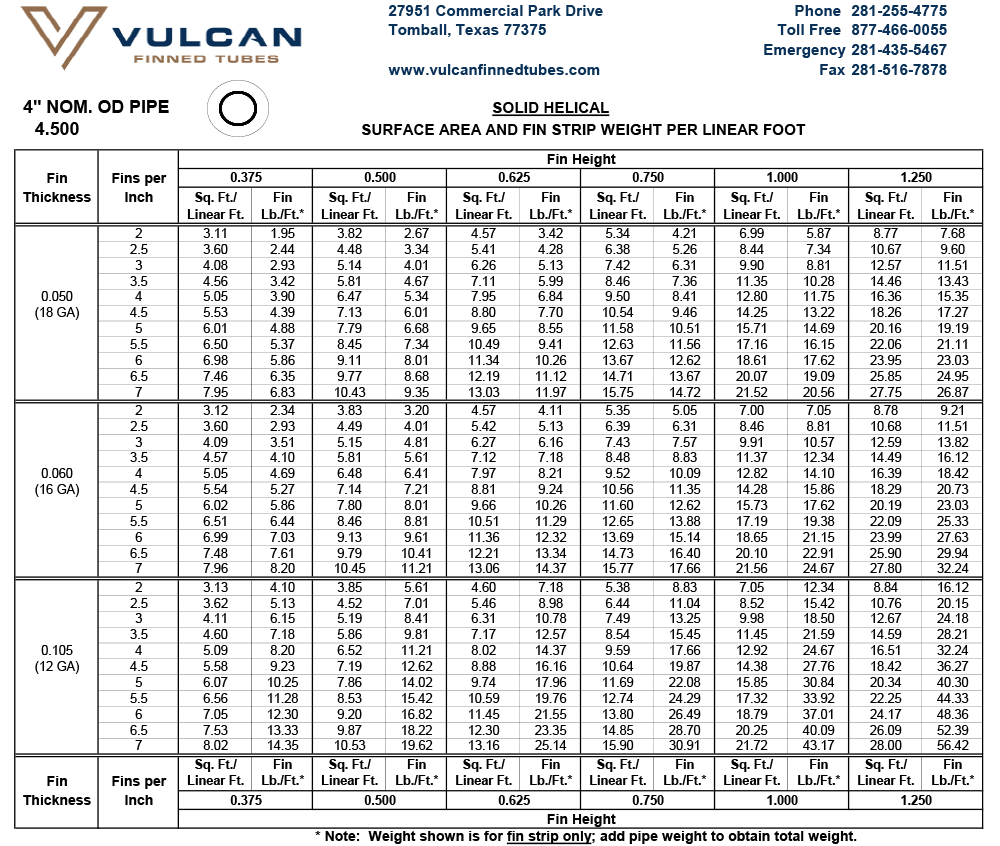

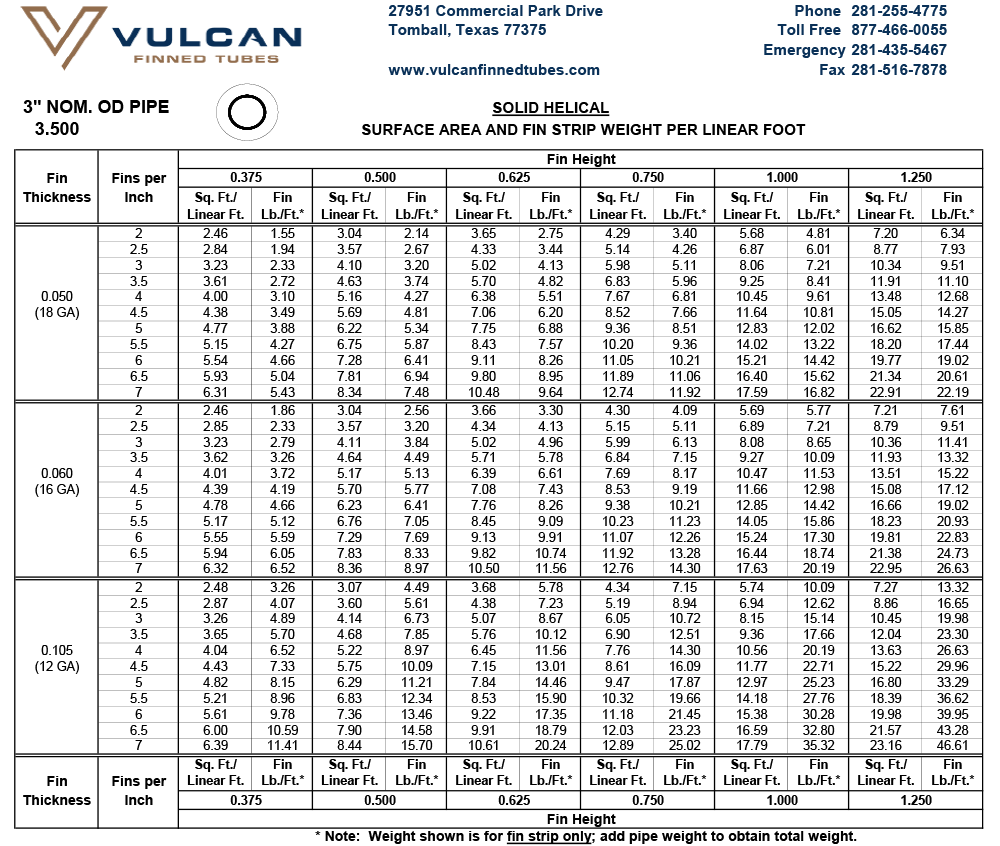

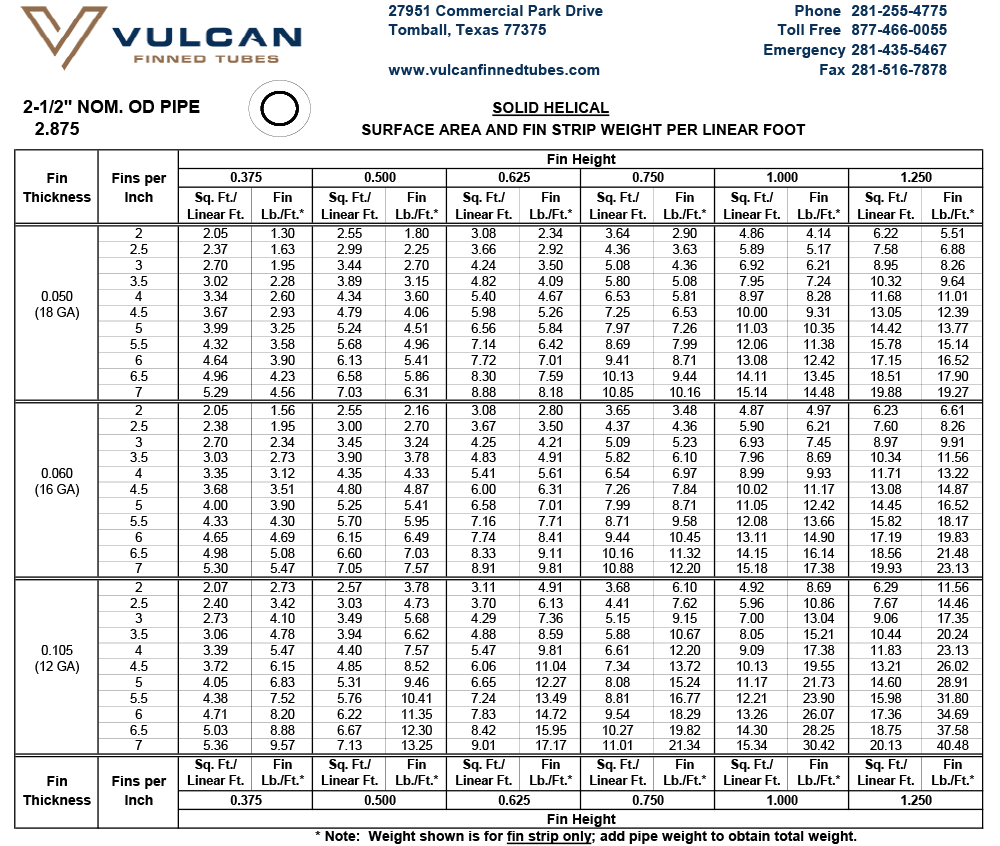

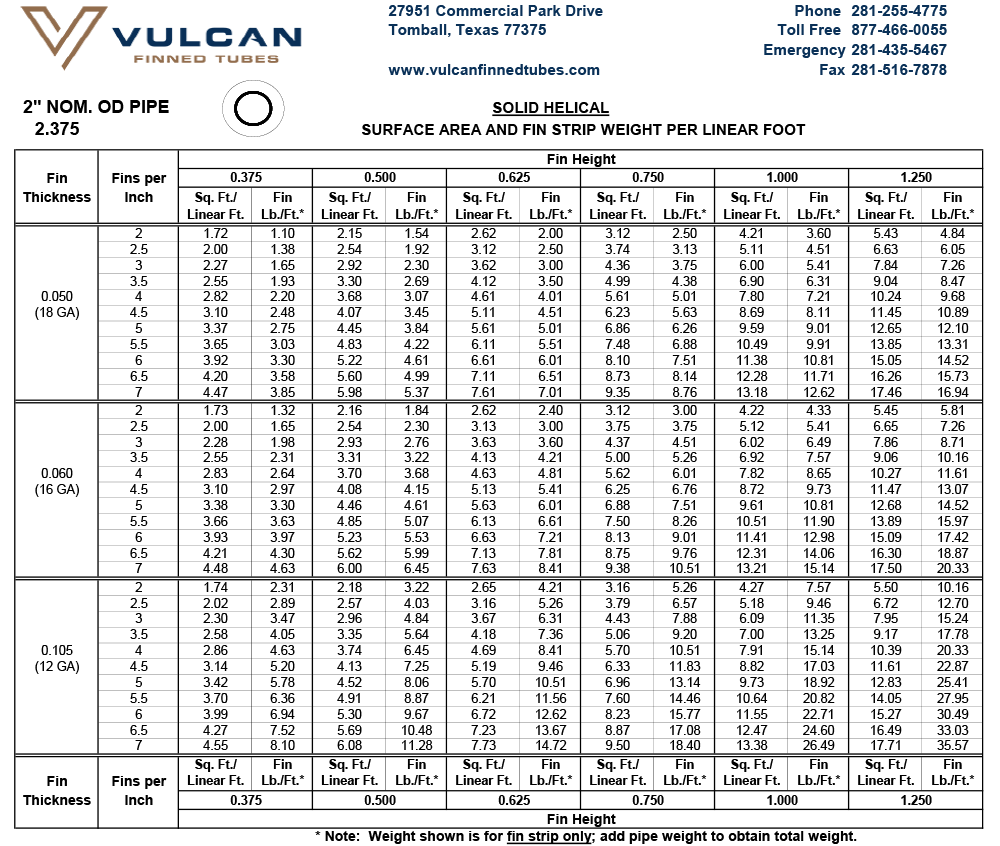

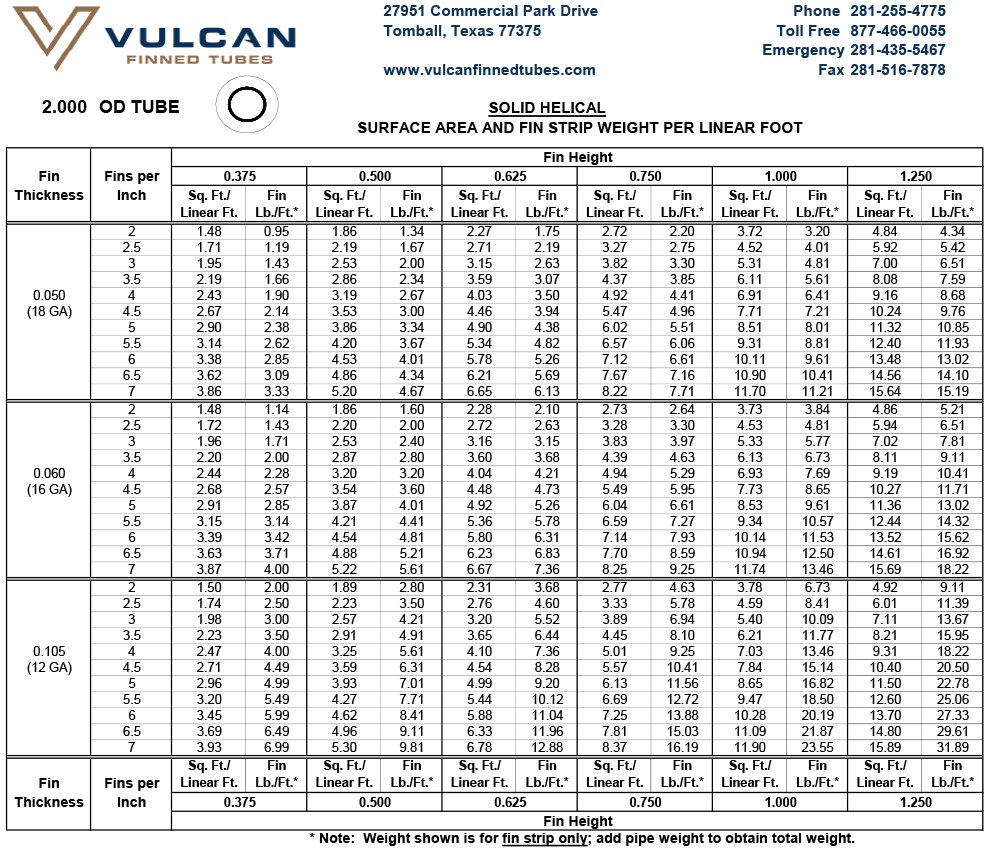

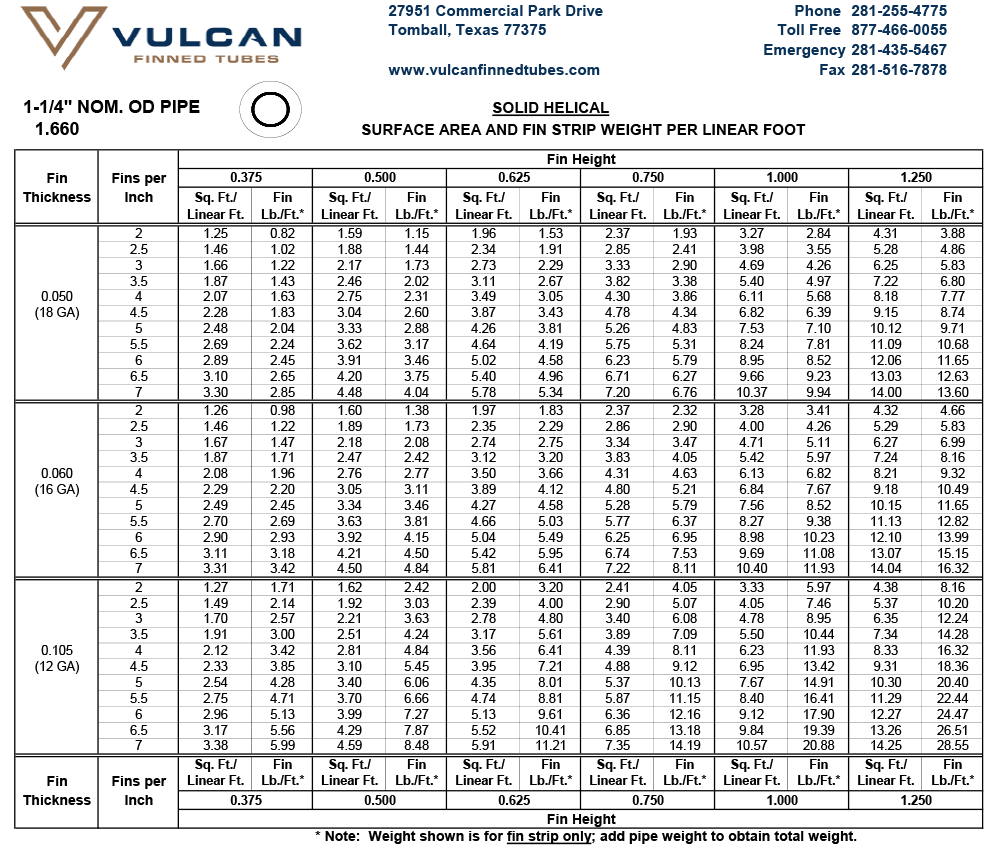

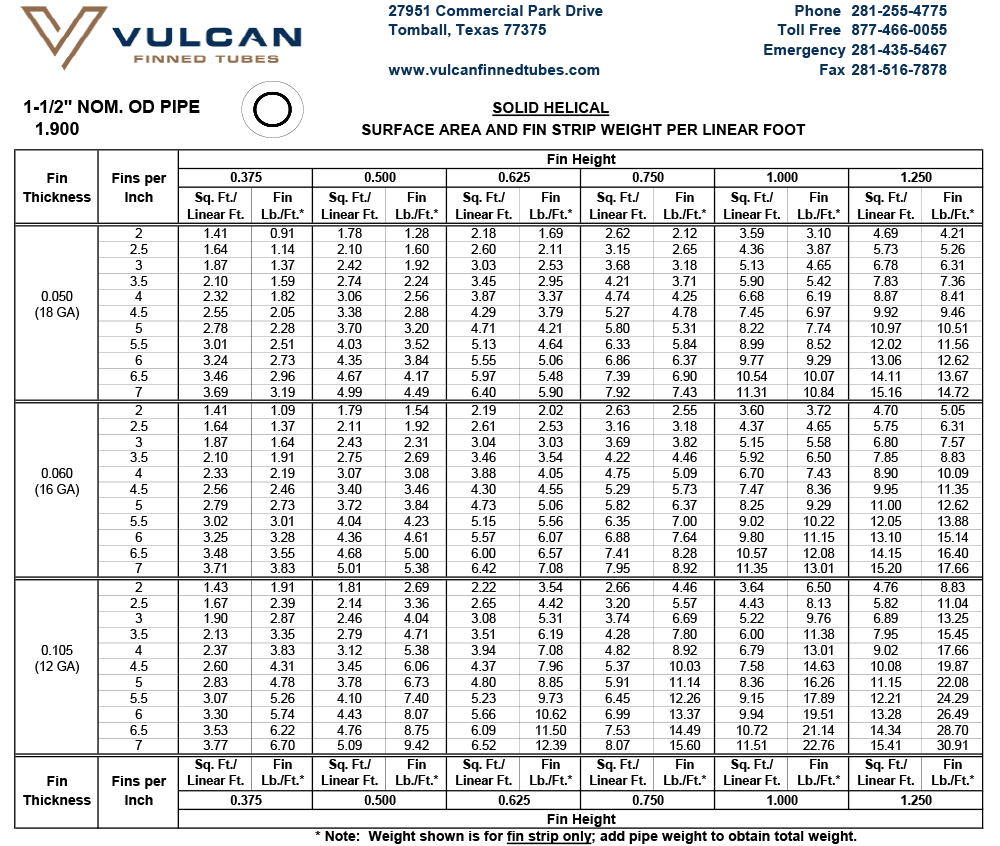

For a given pipe or tube size, the desired heat transfer surface area per unit length of tube can be obtained by specifying the appropriate fin height, fin thickness and number of fins per inch. See Design Information for extensive tables of surface areas and fin weights.

The following table shows Vulcan’s manufacturing capabilities for helical solid finned tube:

| Weld Process | GMAW |

| Tube/Pipe Size | 1.00″ to 12.75″ outside diameter |

| Fin Height | 0.375″ to 1.25″ |

| Fin Thickness | 20ga (.035″) to 12ga (.105″) |

| Fin Pitch | 1 to 7 fins per inch |

| Materials | Any material combination that can be arc welded |

| Tube Length | No practical limit |

* This table should be used as a general guide to our capabilities for Welded Helical Solid Finned Tubes. Grade of material, tube outside diameter to fin height and other factors may limit these capabilities. Please call us for guidance when designing your next finned tube.

This solid fin configuration can be used for practically any heat transfer application, and is particularly suited to high temperature, high pressure applications with high fin-side temperatures. Solid fin can be supplied with thicker fins than the serrated fin, which can be an important factor when dealing with extremely corrosive or erosive environments. Solid fin is typically the fin configuration of choice where severe service environment is expected, or when dealing with fibrous or sticky fluids, which can cause fouling and repeated cleanings.

To learn more about this product see Vulcan’s Standard Specifications for Welded Helical Solid Finned Tubes.